Effective supply chain solutions nz are all about stopping those sneaky, hidden costs from draining your profits. They do this by tightening up everything from how you manage inventory to that crucial final delivery. For so many Kiwi businesses, what feel like minor hiccups—a delayed shipment here, a stock mix-up there—are actually signs of a bigger problem. A problem that's quietly eating away at your bottom line.

Let's be honest. For most business owners in New Zealand, the supply chain is that complicated, messy thing just humming along in the background. It’s easy to adopt an 'out of sight, out of mind' attitude. But what if it’s the silent partner secretly nibbling away at your profits?

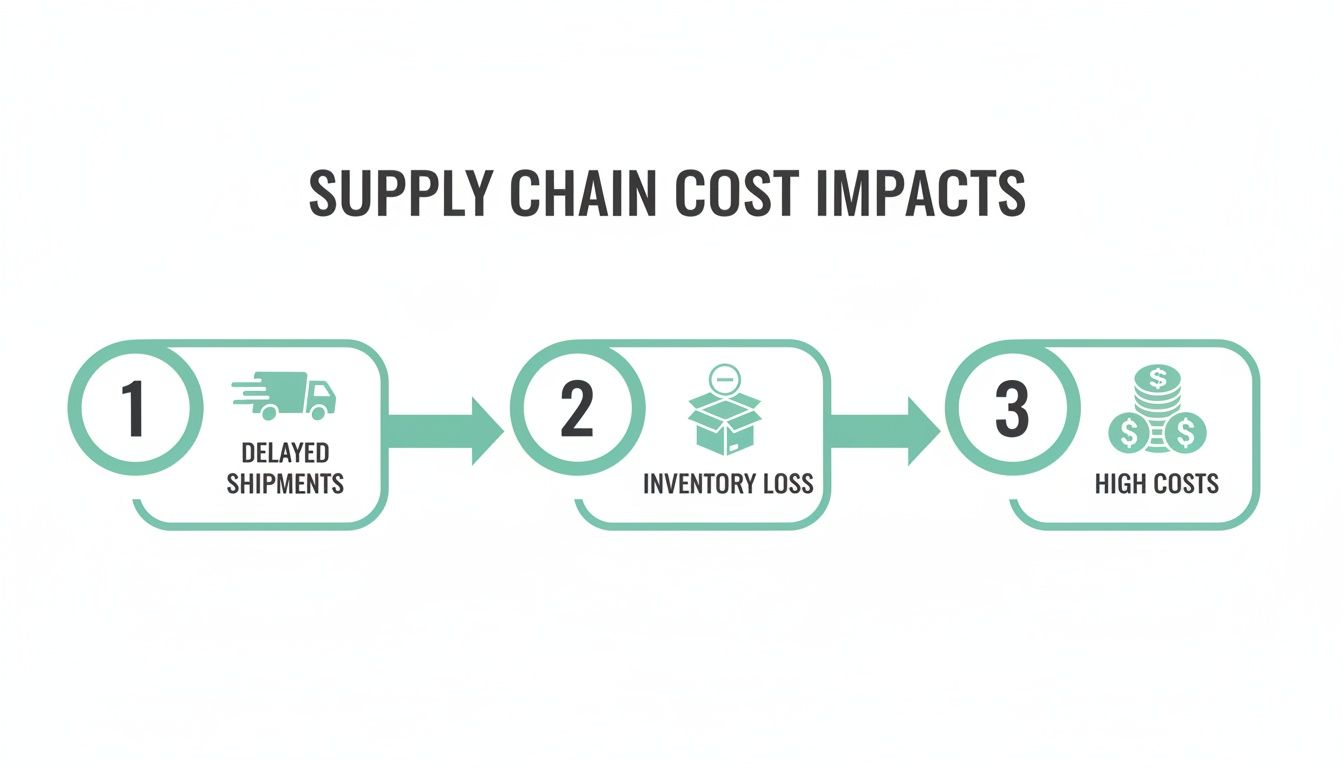

It often starts small. A few delayed shipments frustrate your Auckland customers. Some stock seems to have vanished from the Christchurch warehouse. These feel like isolated incidents, just part of the cost of doing business, right?

Probably not. These are the classic early warning signs of a supply chain that's starting to buckle under the strain.

Think about the real cost of these "small" problems. It's not just the dollar value of the lost stock or the extra freight charge for a late delivery. It's the time—your most valuable asset—that you and your team spend putting out fires.

How many hours a week does someone spend chasing suppliers, recounting inventory, or apologising to a customer?

That time adds up, fast. It's time that could be spent growing the business, talking to new clients, or refining your products. Instead, it gets sucked into a vortex of operational chaos. The financial bleed is very real, even if it doesn't show up as a single, neat line item on your P&L statement.

Here are a few questions to ask yourself:

An often-overlooked area where money is quietly being spent is on outdated communication systems. It's worth exploring what to look for in a modern fleet communication system to see if that's a source of inefficiency for you.

It's not about blame; it's about spotting the hidden opportunities. A well-oiled supply chain doesn't just save you money—it gives you back time and massively reduces everyone's stress levels.

Consider this a friendly reality check. These aren't just "growing pains"; they're symptoms of a deeper issue that needs a proper solution. By asking these direct questions, you can start to properly diagnose the health of your current setup. The goal is simple: to stop the quiet financial leaks and turn your supply chain from a cost centre into a genuine competitive advantage.

So, you have a feeling that something in your supply chain needs to change. But where do you even start?

Honestly, one of the biggest mistakes I see Kiwi businesses make is jumping straight to a flashy new software solution without properly diagnosing the problem. Let's not do that.

Instead, the first, non-negotiable step is to map out your current process. This isn't about creating complicated flowcharts; it's about playing detective inside your own business. We need to figure out who does what, where things get stuck, and what the real, on-the-ground bottlenecks are.

The goal here is simple: get a crystal-clear picture of what you actually need to fix before you spend a single dollar.

You can't fix what you can't see. The best way to start is by tracing an order’s entire journey, from the moment a customer clicks "buy" right through to when it lands on their doorstep. This means having real, honest chats with your team—the people in the trenches who deal with the friction every single day.

Go talk to your sales reps, your warehouse crew, and your admin staff. You might be shocked at what you uncover. Often, a major shipping delay has nothing to do with the freight company; it’s actually caused by a small communication breakdown between sales and the warehouse.

These seemingly minor hiccups quickly compound and start eating into your profit margin.

As you can see, problems like shipping delays and stock losses aren't isolated incidents. They're all connected, and they all lead back to higher costs for your business.

To get the ball rolling, I've put together a simple checklist. Use this to pinpoint the primary challenges in your current supply chain operations. Don't just think about these questions—grab a pen, write down the answers, and then discuss them with your team.

| Area of Operation | Key Question to Ask | Yes/No/Partial |

|---|---|---|

| Order Entry | Is order information entered into our system automatically and accurately, without manual keying? | |

| Inventory Management | Do we have a live, reliable view of our stock levels across all locations at all times? | |

| Picking & Packing | Can our team consistently pick, pack, and prepare an order for dispatch within our target timeframe? | |

| Shipping & Dispatch | Is courier/freight booking automated, and is tracking information sent to the customer without manual intervention? | |

| Customer Communication | Are customers proactively notified about order status, delays, and delivery? | |

| Returns Process | Do we have a clear, efficient process for handling returns that gets stock back on the shelf quickly? |

This exercise isn't just about finding faults. It's a powerful first step in building the business case for the right supply chain solutions NZ has to offer.

By answering these questions honestly, you're not just identifying problems. You're building a business case for change. You're gathering the exact evidence needed to justify investing in a solution that targets your real pain points, not just the ones you assume you have.

This map is your foundation. It stops you from buying a powerful piece of warehouse software when your biggest issue is actually how orders are processed at the very beginning. Getting this right saves you time, money, and a massive headache down the line. It ensures you focus on what truly matters.

Alright, you’ve mapped out your processes and pinpointed exactly where things are getting bogged down. Fantastic. Now you've arrived at the big fork in the road: do you grab an off-the-shelf software that seems to do it all, or do you invest in a solution built from the ground up, just for your business?

It’s a classic Kiwi dilemma, really. The old number 8 wire approach versus buying a shiny new tool from overseas. Both have their place, so let’s get down to brass tacks.

Off-the-shelf systems can seem like a quick win. They're often cheaper upfront and get you going fast. But here's the catch—you often end up trying to jam your unique, successful processes into a rigid system that was never designed for them. It just doesn't quite fit.

A custom-built system is tailored perfectly to your workflow. Think of it like a bespoke suit versus one off the rack. It’s designed to handle all the specific, sometimes quirky, tasks that make your business tick and give you that competitive edge. This is your chance to automate the very things generic software can't touch.

The tipping point often arrives when your operations grow in complexity. If you're juggling multiple suppliers, have unique product handling requirements, or a specialised delivery network, a generic system will start to creak at the seams very quickly.

The real question to ask is: Does the software serve our process, or do we have to bend our process to serve the software? If it's the latter, you're almost certainly leaving efficiency and money on the table.

This isn't just a small decision; it's about laying a foundation that will support your business for years to come. To explore this choice in more detail, you might find our full guide on custom software vs off-the-shelf options in NZ helpful.

Think about where you want your business to be in five years. Will that off-the-shelf solution still be cutting it, or will it become a roadblock to your growth? A custom solution is built with your future in mind, designed to scale and adapt as your business evolves.

The market for these tools is booming for a reason. New Zealand's supply chain automation market is now valued at around USD 1.1 billion, with Warehouse Management Systems (WMS) leading the way. This growth is driven by a real need for Kiwi businesses to get smarter with their inventory and logistics. You can learn more about these market findings to see why so many are making a change.

Here’s a simple way to frame your decision:

Ultimately, choosing the right supply chain solutions NZ has to offer is about finding the best fit not just for today, but for the future you're busy building.

So, you’ve found a potential solution. Brilliant. Now for what I’ve seen time and time again be the trickiest part of the whole project—making it play nicely with everything you already use. Honestly, this is where so many well-intentioned projects fall over, and it's a heartbreaker to watch.

A shiny new system that can’t talk to your existing tools isn't a solution; it's just another expensive headache.

Think about it. If your new inventory system can’t automatically tell your Shopify store that a product has just sold out, what have you really gained? All you’ve done is create a new manual task for your team and, worse, a new way to disappoint a customer.

This is what we call the integration puzzle. A genuinely effective supply chain solution for NZ businesses connects the dots; it doesn't create more silos of information.

How do different pieces of software actually talk to each other? They use something called an API, which stands for Application Programming Interface. The best way to think of an API is like a waiter in a restaurant. You (one system) tell the waiter your order. The waiter takes it to the kitchen (the other system) and brings back exactly what you asked for. You don’t need to know how the kitchen works; you just need a reliable way to communicate.

This is how the real magic happens in your business. It’s how shipping updates from your courier can flow directly into your customer service software, letting your team answer queries instantly. It’s also how sales data can seamlessly link up with your customer relationship management tools, giving you a much clearer picture of your business. If you're looking to improve this area, understanding more about CRM and automation development for NZ businesses is a great next step.

A solution without strong integration is like hiring a new team member who refuses to speak to anyone else in the office. They might be brilliant at their one task, but they’ll quickly become a bottleneck for everyone else.

For most Kiwi businesses I work with, there are a few non-negotiable connection points that any new system must handle. Planning for these from day one will save you a world of pain down the track.

The New Zealand freight and logistics market is valued at USD 18.51 billion and is projected to hit nearly USD 22 billion by 2030. This growth is pushing logistics companies to partner with digital platforms for better visibility, making these integrations more important than ever. You can read the full research on the NZ logistics market to grasp the scale of this opportunity.

Getting these connections right isn't an afterthought; it’s the absolute core of the project.

So, you’re at the pointy end of choosing a new system. It’s a moment that can feel genuinely daunting for any business owner. Will it break everything? Will the team revolt? Will your customers even notice—or worse, notice for all the wrong reasons?

Let’s just pause for a second. A successful rollout isn't about flipping a big, scary switch and hoping for the best. It’s a planned, careful process, and getting it right is less about technical wizardry and more about smart, human-focused planning.

Before you commit the entire operation, why not test the waters first? A pilot test is your secret weapon here. Instead of deploying the new system across the whole business at once, you introduce it into a controlled, low-risk corner of your operations.

What could this actually look like in practice?

This approach lets you find and squash the inevitable bugs before they become major headaches. Think of it as a dress rehearsal. You get to see what works, what doesn’t, and make adjustments without betting the whole farm.

Here's a hard truth I've seen play out dozens of times: the best software in the world is completely useless if your team doesn't understand it or, even worse, doesn't want to use it. Proper training is absolutely non-negotiable for any new supply chain solutions NZ businesses adopt.

And by training, I don't just mean a quick demo on which buttons to click. You have to explain the why.

Why are we changing the dispatch process? Because this new scanner will reduce mis-picks by 20% and get orders out the door an hour faster. Why do you need to scan every single item? Because it gives us live inventory data, which means fewer stockouts and much happier customers. When people understand the reason behind the change, they’re far more likely to get on board.

Getting your team's buy-in isn't a "nice-to-have," it's the entire game. The new system's success depends almost entirely on the people who will be using it every single day.

You've gone live. Phew! But the job isn't over. In fact, the first three months are the real optimisation phase. This is when you turn a good system into a great one that’s perfectly dialled in for your business.

You need to be watching your key metrics like a hawk. What’s working well? What’s still a bit clunky or causing frustration for the team? Keep the lines of communication wide open—your people on the floor are your eyes and ears.

Keep a close watch on a few key numbers:

Tracking this progress is a core part of good project management, and it’s a discipline worth mastering. You can find some excellent, practical advice on successful project management in NZ that applies perfectly in this situation. The small, continuous improvements you make in these first 90 days will pay dividends for years to come.

We spend a lot of time talking to Kiwi business owners about their supply chains, and we hear the same questions pop up again and again. It’s a world filled with jargon and complexity, so let's cut through the noise and tackle the big ones.

Honestly, you don't always need a massive, ground-up overhaul to see results. Sometimes, the biggest wins come from small, smart improvements and just getting a clearer picture of all the moving parts.

Ah, the million-dollar question. The honest answer is, "it depends." You could be looking at a few hundred dollars a month for an off-the-shelf software subscription, or it could be a significant five or six-figure investment for a fully custom-built system.

But that’s not really the right way to think about it. The real question is, "What's the cost of doing nothing?"

If your current setup is bleeding $10,000 a month in wasted staff time, lost stock, and freight mistakes, then investing in a solution that plugs those holes delivers a very clear return.

The goal isn’t to find the cheapest option; it’s about finding the one that delivers the most value. Focus on the return on investment (ROI), not just the upfront price tag.

Easy. They underestimate the complexity of their own operations.

We see it all the time. A business owner thinks they just need a simple tool to track inventory. But they forget that tool also needs to talk to Xero, automate courier bookings, handle customer returns, and send out delivery updates. They fix one small problem but accidentally create three new, bigger ones.

This is exactly why mapping out your entire process—from order to delivery and back again—is so critical before you even start looking at software. You have to see the whole picture to find a solution that actually fits.

Even if you only sell within New Zealand, there's a good chance your supply chain has global touchpoints. Where do your raw materials come from? Where are your products manufactured?

For any business involved in international trade, getting your head around the key roles and responsibilities is vital. A classic example is the Importer of Record (IOR), which is the person or entity responsible for making sure imported goods comply with all local laws. Getting this wrong can lead to costly fines and your shipment getting stuck at the border. There's a complete guide to the Importer of Record that explains these duties really clearly.

New Zealand’s supply chain has grown far beyond simple domestic networks. Today, road transport still handles the majority of domestic freight at 60%, but that local leg is often just the final step in a much longer international journey. You have to think about these global connections to build a truly solid operation.

At NZ Apps, we don’t just build software. We partner with businesses to solve real-world operational problems.

If you're ready to stop putting out fires and start building a more efficient, profitable supply chain, let's have a chat. Book a free, no-obligation consultation with us today and we can explore what's possible.